Solutions

CAD>CAM>CAE Core technology provided by Myrtos Corporation

From Consulting to the Introduction of Specific Application tools

for the Development Productivity Improvement

Solution Proposal from upstream to down stream

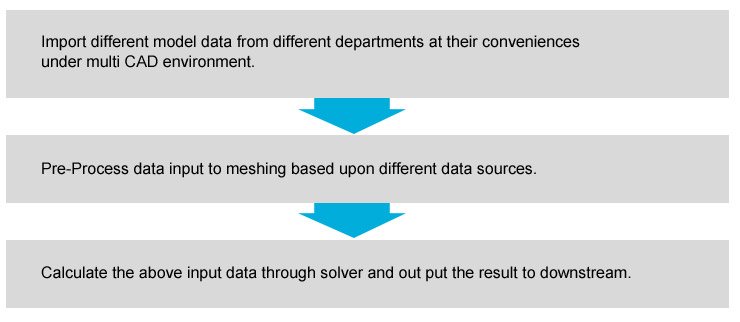

Current developers are requested to reach optimum production system throughout design and production after repeated synthesis with analysis,by taking advantage of original 3D data of CAD/CAM/CAE.

“Bring Optimum Design by Analysis through Production Process under Seamless Environment”

This is an essential measurement for every manufactures.

But we , Myrtos , detect the significance of “the Slush between CAD/CAM/CAE”.

Have you encountered following issues during the above process?

Trouble becomes inevitable by such data transaction!

Change "Inconsistent" stream of CAD/CAM/CAE to "Consistent" CAD>CAM>CAE (by the transformation of original data)

Lack of the "Consistency" of data between “CAD/CAM/CAE today incurs not only unnecessary work and time loss , but also less dedication to the real business that requests developers to compress the lead time to market.

Myrtos provides customers with breakthrough technology of package software or middleware and consulting for reengineering development process.

Myrtos leads customers to consistent “CAD-CAM-CAE” environment out of inconsistent "CAD/CAM/CAE".

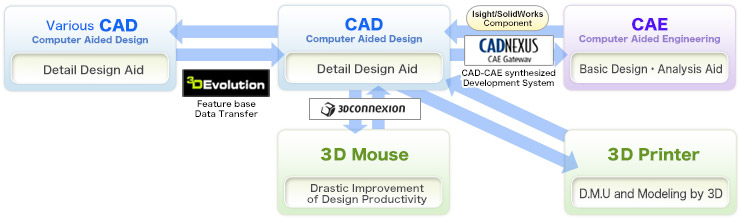

Solutions Map that Myrtos provides

Dynamic Solution to Emancipate “Death Valley Slush” from "CAD/CAM/CAE" to "CAD-CAM-CAE"

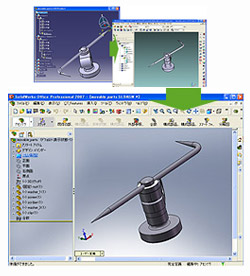

「CADNexus/CAPRI 」provides seamless “CAD-CAM-CAE” Environment. CAPRI is a revolutionary technology of bidirectional data transfer. Designers can obtain optimum shape through bidirectional data transfer going back and forth by repeated parametric change of meshing. This methodology enables designer automate ideal design shape in most efficient manner.

「3D Evolution」provides data transfer between main CAD systems , including Feature Information(Design Intent). It makes data transfer possible between different CAD systems and different versions for the customers of multi CAD/Versions. This technology is getting more valuable not only between OEM and suppliers but also inside the same company that carries multi CAD systems as a result of M&A.

Emerging Technology to improve the accuracy and efficiency of the development

Accelerate Development Speed at Mock up or Prototype Making

Demand for 3D Printer is seriously requested these days to overcome the inconvenience of real recognition of products served by 3D image on virtual display. 3D Printer enables output of actual cubic shape at every stage of development. It enables the output of product shape directly on demand. You can secure drastic improvement of development efficiency and accuracy of product output by cutting off time and cost for making mock up and prototype.

We can provide you with 3D Printer as front runner in the world of 3D Printer “Markforged”.

The Printer , with fulfillment of space saving and affordable price setting , makes 3D models by the layers of PVC FILMS with glue in between from 3D data by CAD , Scanner or any 3D file data such as STL , etc.

3D Mouse demonstrates the power to be cumbersome mouse operation

Mouse operation by 2D mouse is complicated during the visualization of 3D data for rotating model. 3D mouse makes it easy for the selection of menu command , model rotation , pan ,zoom in and out.

3D mouse “3D Connexion” can make those operation intuitively with the felling as if object are handled freely by engineers own hands.

We are the japanese agent for “3D Connexion” SAM. We also meet various needs by architectural development and Graphics on top of mechanical demands.